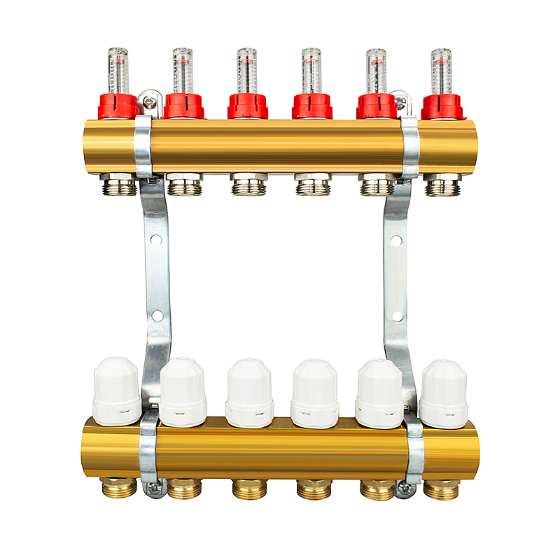

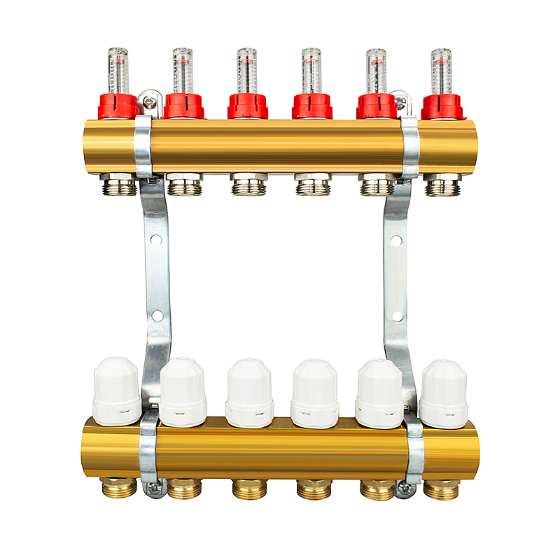

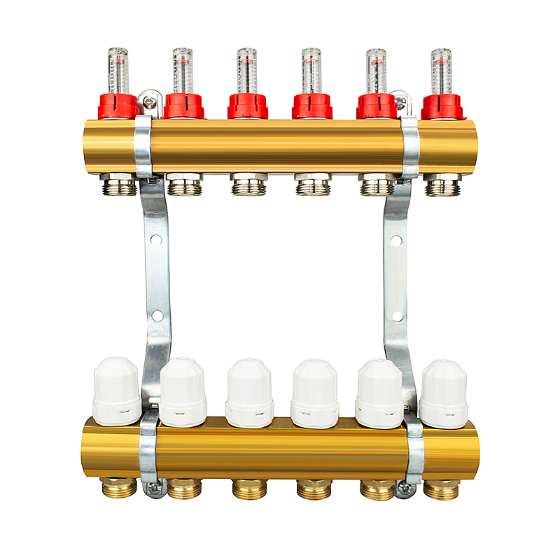

Underfloor heating manifold 2 sections

- Bar width:

- number of circuits: 2

Do you value your own comfort, and low temperatures scare you? You don't have to travel to exotic places just to feel some warmth. It's something you can find at your own home - just use the modern underfloor heating manifold. It's definitely much cheaper solution.

The underfloor heating manifold is exceptionally durable. We have used the best materials for its production. Brass bars and strong holders made of steel allow you to create a functional underfloor heating system that is going to last for a long time.

The radiant heating manifold is available as a set with all necessary elements needed for its proper work and installation. They are:

Pay for the set - and save money! You can also be sure that all parts fit each other perfectly.

Is it difficult to control the manifold? Not at all! The rotameters included in the manifold set allow to control the water flow in the heating system. Inside, there is a floater - it indicates the level. You can control it at any moment thanks to the scale on the side of the rotameter.

The manifold has been equipped with control valves, to give you an easy control over the water flow and temperature in the system. All you need to do is tighten the valve if it is too hot in the room, or unwind it if the temperature drops. It's you who decide about your thermal comfort.

There are brass nipples on the manifold bars. Thanks to them you can quickly attach the manifold to the supplying conduits and return pipes. It's very easy, which makes the solution very functional.

Manifolds are the basic products used in heating systems - mostly for underfloor heating. The main purpose of this element is to connect, cut off and regulate several heating circuits. Thanks to this one can get various parameters for each of them. In addition, manifolds can be also connected to a mixing valve.

Underfloor heating conduits - that is, water pipes - are placed under the floor. They often form looped sections. The implementation of a manifold in such case is crucial. It makes the heat spread evenly in each room connected with the system. Moreover, underfloor heating manifold can be controlled by the user, who can choose the right temperature fit to their individual expectations.

Surprisingly, the underfloor heating manifold is not very complicated. Each of its elements meets particular requirements and serves a specific purpose. The basic part of each device are brackets. They allow to install the manifold in a cabinet.

Radiant heating manifold contains two bars. The lower one is called the return and the upper the supplying bar. Depending on the model - an underfloor heating manifold can control from 2 to 12 circuits.

Nipples placed on both bars allow to quickly connect the circuits to the manifold. It’s very easy as well. The lower bar is equipped with additional regulating (thermostatic) valves. You can use them to manually regulate the temperature in a room.

The upper bar contains flow meters. The rotameter allows you to control the flow of the water. The value of this parameter is determined by a float in the control pipe. There is a clear scale on its wall, which shows the intensity of the flow.

Many manifold models have an air vent installed on the bars. It’s a very important element - it removes the air from the system. Excess gas in a heating system might cause noise in the pipes, and it might disrupt the heating process in the long run.

The radiant heat manifold is available with all elements needed for its installation. The most important part involves attaching the holders to the manifold’s bars. The frame eliminates vibrations which could disrupt the manifold’s work. Another important aspect is placing the bars, following the manufacturer instructions. The supply bar should be in the upper part and the return bar - at the bottom. It’s not difficult to do, and nobody should have any problem with it.

Attaching the pipes to the manifold is not very complicated, either. It’s easy, thanks to the aforementioned nipples - they significantly reduce the time of installation.

When choosing equipment such as a manifold for underfloor heating, pay close attention to the number of circuits that can be attached to the bars. It’s a parameter strictly connected to the construction of the installation and the size of the unit that is going to be heated by underfloor heating. Very large buildings typically use several manifolds.

The price of a manifold is a value that grows proportionally to the number of circuits that are going to be attached to it. The simplest models for just two circuits are definitely cheaper than 12-circuits manifolds. It is best to choose a manifold made of high-quality materials from a good manufacturer.